Rolex ceramic bezel (Rolex Cerachrom) complete guide

The Rolex ceramic Cerachrom bezel is an important feature of a Rolex timepiece. They are instantly recognizable, not to mention the bi-colored ceramic bezels that some watches use.

But what is the Rolex ceramic bezel? How is it made and what purpose does it have?

Let’s go into detail about this very interesting Rolex part.

Rolex ceramic bezel – Rolex Cerachrom

Rolex, who is known for coming up with its own names for its materials to make them appear more unique and exclusive, calls its ceramic bezels ”Cerachrom”.

The name is a combination of the words ceramic and Chrom. Chrom means color in Greek.

Rolex developed and patented the Cerachrom bezel in 2005. They are made specifically for professional models which feature a bezel that is possible to operate (rotating bezels).

Why did Rolex see the need for developing and introducing the ceramic bezel? The short answer is that the aluminum inserts which were previously used didn’t offer the long-lasting durability that Rolex wants in each and every single part of its watches. The issue with aluminum inserts is that they scratch and fade over time. This can be seen on vintage watches, where the color of the bezel has faded completely, plus where the insert is, of course, full of scratches.

Rolex strives to make watches that look just the same for generations to come, without getting signs of aging such as patina. One such step in that direction was the introduction of the Cerachrom bezels.

The benefit of Ceramic is that it does not fade. Additionally, the bezels are virtually scratch- and corrosion-proof which means that the ceramic bezels have long-lasting qualities. This is a great thing considering that the bezel is the most exposed area of a watch, meaning they are prone to physical impacts.

The ceramic bezels are diamond-polished, which is what gives the ceramic an unmistakable luster. The engraved graduations are also coated with a layer of platinum or gold depending on the model. Rolex does this because regular paint will naturally wear off over time. The markings on the ceramic bezels are not only painted but also recessed to ensure optimal readability.

Which was the first Rolex to use a ceramic bezel?

The first model to use a ceramic bezel was the GMT-Master II reference 116718, which was released in 2005.

Rolex Cerachrom production

In true Rolex fashion, the company developed an in-house division dedicated to ceramic bezels. The introduction of ceramic also required new technology and equipment.

Rolex’s Cerachrom manufacturing is located in the factory which is situated in Plan-les-Ouates, just outside of Geneva. The fact that the cerachrom bezels are entirely made in-house gives the company full control over the manufacturing process but also gives them full freedom to experiment and innovate. Just the way Rolex likes it.

In the early stages of the Rolex Cerachrom production, the company struggled to make bi-colored ceramic inserts. Getting the colors to meet just perfectly is a tough challenge as ceramic is not an easy material to work with, to say the least. It makes sense to use a bi-colored bezel on GMT watches, so it is easier for the wearer to keep track of day and night. With aluminum bezels, it was easy as simply printing the color onto the bezel, but with ceramic, it’s not like that.

The first bi-colored ceramic bezel was launched in 2013, with the reference 116710BLNR. Note that this is eight years after Rolex first presented the Cerachrom bezel. So after 8 years of production, Rolex had finally perfected its craft in making bi-colored ceramic.

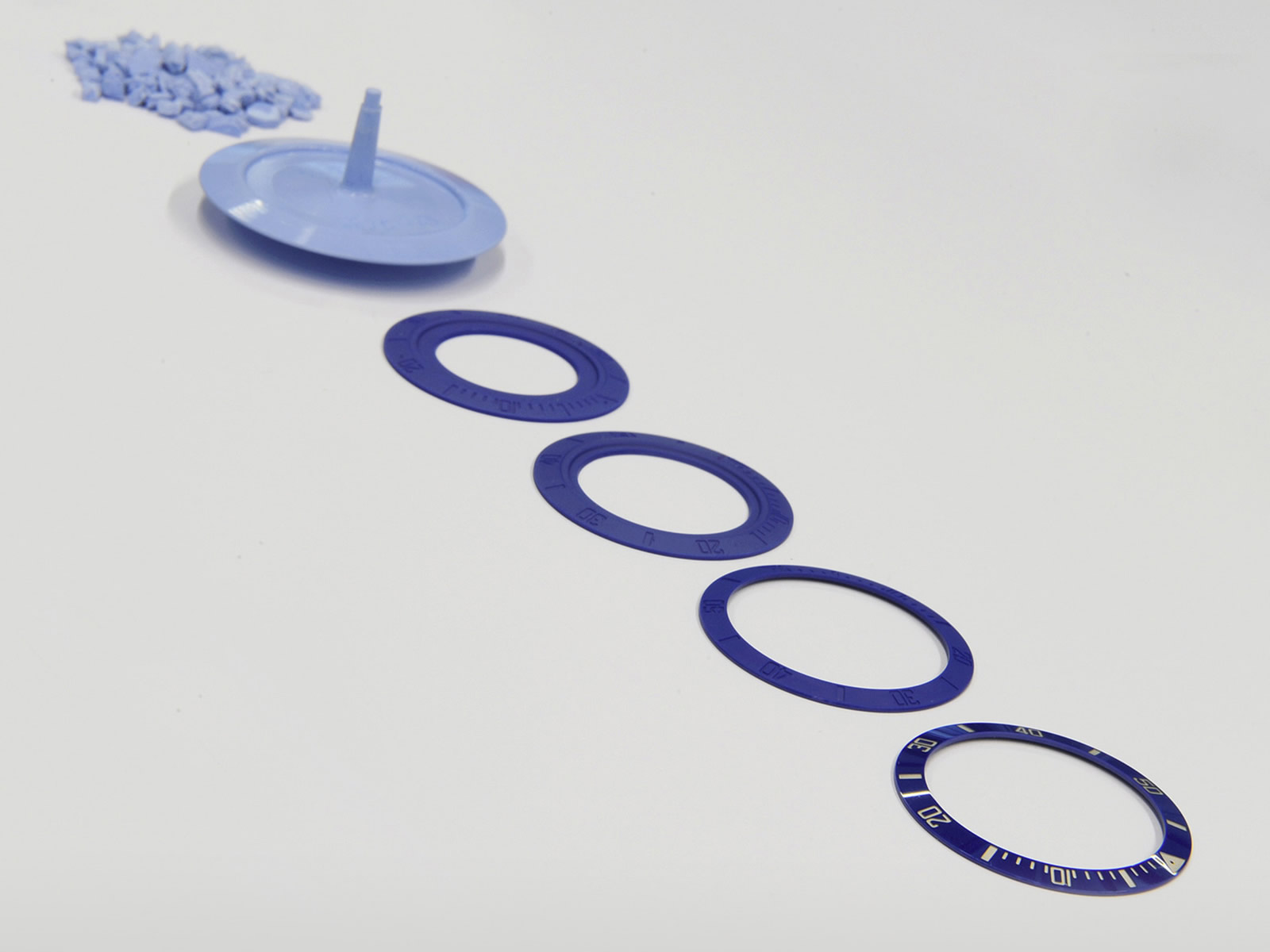

Rolex is very secretive about most of the manufacturing of its watches, but the company has shared some images of the ceramic bezel from scratch to finished product, which gives us an insight into how the company makes it.

The ceramic bezel starts out with a powdered ceramic mixture. This is two-color pigments, by the name of ZrO2 and Al2O3. Binding agents are then added, and it is then heated and placed into a mould. Once this process is complete, we have rings with numerals and inscriptions.

After this, the insert gets heated again at extreme temperatures (heated to 1500 degrees Celsius) in order to remove the binding agents. This process is known as sintering and is done to harden the insert, shrink, and give it its vibrant color and luster. During this stage, the insert shrinks by 25%.

During the sintering, the chemical components which are introduced, react with the ceramic’s oxides which causes the color to change. The color is achieved when the insert is cooled down.

For the bi-color versions, half of the ring is then chemically treated. Following, the ring is heated under pressure. According to Rolex, it takes 40 hours to make a bezel.

Photos via Horobox and Rolex.

I sure would like to be a fly on the wall

And watch from start to finish to see how these bezels are exactly made.